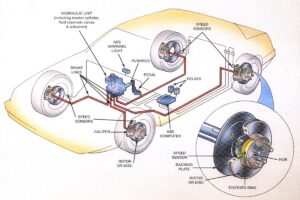

Ensuring Safe Braking: A Guide to Brake Preventive Maintenance

A Guide to Brake

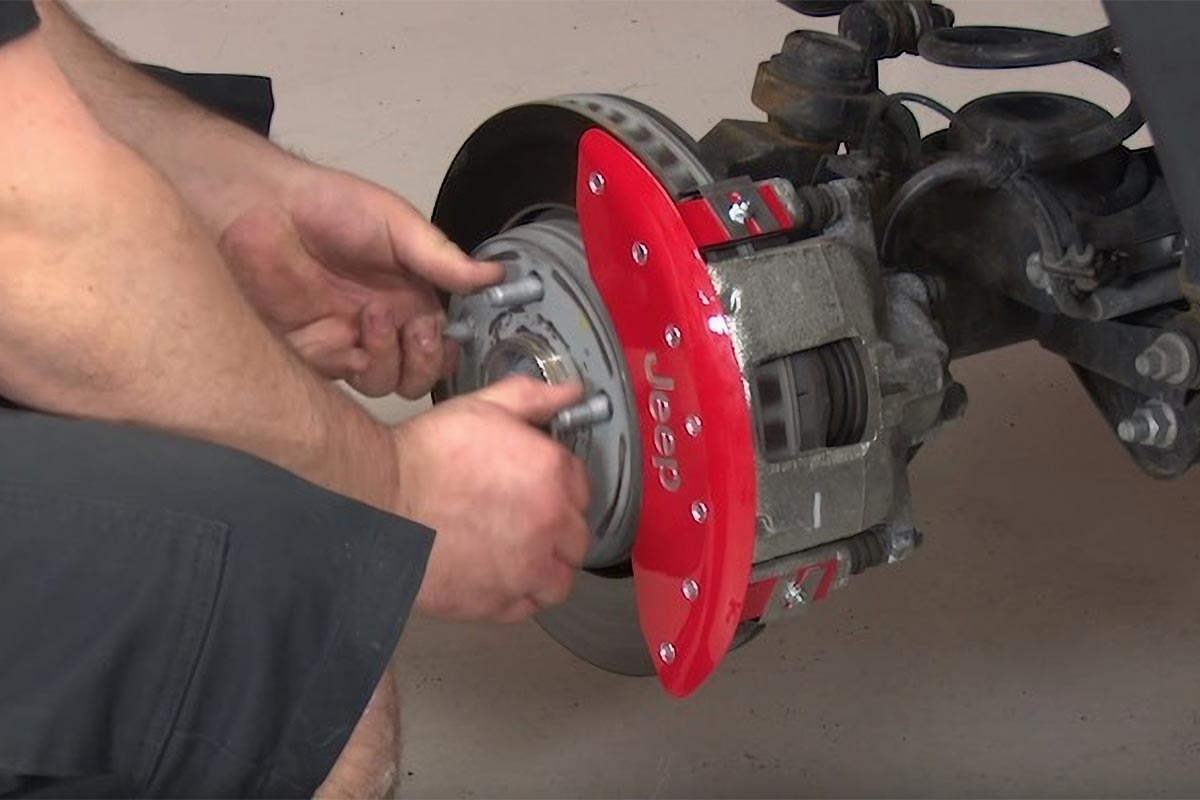

Home » How to Inspect Disc Brake Calipers on a Jeep or Tacoma

If you’ve got more than 100K miles on a set of calipers, they probably need to be replaced. If you live in the salt belt (the northeast and upper midwest regions in the US), you’ll likely need to replace your calipers sooner. The best way to determine if your calipers still have some life left in them is to physically and visually inspect them.

There are two basic types of calipers on the market. It’s good to understand which type your Jeep or Tacoma has before inspecting your calipers.

If you have a Jeep JK, then you have floating calipers. The Jeep JK floating caliper is conventional single piston design.

The caliper is mounted on guide pins that are bolted to the caliper bracket. When you apply the brakes, the piston presses the inner brake pad against the rotor. This force also simultaneously pushes the floating caliper towards the vehicle, and the outer side of the caliper brings the outer brake pad into contact with the rotor. The caliper “floats” on the guide pins as it moves.

If you have a second or third generation Tacoma, then you have fixed calipers.

Tacomas use a four piston fixed caliper. The caliper is rigidly attached to the steering knuckle. When you apply the brakes, two pistons on each side of the caliper squeeze the rotor. In a fixed caliper brake, the guide pins serve a different purpose than those in floating calipers. They deal with much less force, so they are smaller.

Image Credit: CJ Off-Road

Image Credit: CJ Off-Road

To access your calipers and inspect them thoroughly, you will need to lift your vehicle and then remove the wheels. Be sure to lift your Jeep or Tacoma safely, and always use jack stands.

If you want to conduct a thorough inspection, you would need to examine the following seven items:

Remove the brake pads from the caliper and then take a good look at them.

If the brake pads are worn evenly across the pad, and equally between the two pads, the caliper is operating normally. If the pads show uneven or unequal wear, the caliper either needs to be repaired or replaced.

Look over the caliper housing to see if there are any cracks. If you find any cracks, then the caliper must be discarded. If you continue to use a cracked caliper, then the crack is only going to get bigger and the caliper will fail suddenly. Cracked calipers don’t happen very often. It is usually caused by excessive heat due to a dragging pad.

The dust boot is the visible seal between the piston and caliper. Look for tears in the dust boot, or wear and hardening due to age. A bad dust boot will have allowed water to corrode the caliper bore and piston. If you find a bad dust boot, it is pretty likely that corrosion has already occurred, and you should replace the caliper.

Calipers can leak from two places:

The piston(s) should move easily if hydraulic pressure is released. Sometimes corrosion prevents this. To check the piston(s), follow these steps:

If the piston(s) won’t move, and no fluid comes out of the bleed valve, it is possible that the bleed valve is corroded shut. You can remove it entirely to inspect it.

If the piston(s) does not move freely, you can purchase a rebuild kit and replace only the piston and seals. If you do this, you should also remove corrosion from the piston bore with brake caliper honing tool. The other option is to replace the caliper, which is much easier and possibly more cost effective than rebuilding the caliper.

If you do find that the caliper piston or guides are seized in some way, we advise also replacing the brake hose. Seized calipers generate excess heat. Brake fluid transfers the heat to the brake hose, which degrades and weakens the hose.

Guide pins come with a coating that resists corrosion, but they will still corrode over time. There are two basic styles of guide pins. Jeep JKs have a floating caliper. Floating calipers have guide pins that must be removed with a wrench. The fixed calipers on Tacomas use pins that are retained by a retaining wire. To check the pins:

Some calipers use replaceable pad guides (or slides). These are also coated to resist corrosion, but will eventually corrode. You will need to remove the pads and clean the guides to inspect them. The guides should be smooth and shiny after cleaning.

You’re welcome to contact us if you have any questions about inspecting your disc brake calipers. We’re always happy to assist you!