Ensuring Safe Braking: A Guide to Brake Preventive Maintenance

A Guide to Brake

Home » Brake Pad Materials Explained

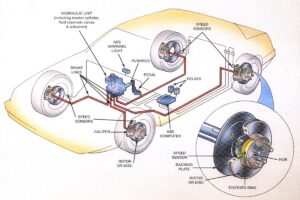

A lot of off-roaders worry that upgrading to bigger tires will affect their ABS system, and cause it to not work as it should. We’re here to tell you that your ABS system will be fine …

Every time you brake, the brake pads are pushed by the brake cylinder against the rotors. The rotors kinetic energy is transformed into heat, stopping the vehicle. The brake pads pressed against the rotor is called friction material or lining compound, popularly known as compound.

You probably heard about ceramic, semi-metallic, and organic brake pads, but what’s the difference between these brake pad materials?

The first ceramic pads didn’t brake well when cold and weren’t advised for daily

driving, but this changed when manufacturers started adding metallic filaments and

other materials to the blend. Nowadays, brake pads are not exclusively made for

exotic vehicles; they are safe to use in all weather and driving conditions. Many

vehicles like the newer Jeep Wrangler come with ceramic brake pads as a factory

equipment.

Even though these brake pads are usually more expensive than semi-metallic pads

and definitely much more expensive than organic brake pads; they are worth every

cent and makes them the best lining compound available in the market for daily,

track, and off-road use. They last much longer than brake pads made of other

materials, go easy on the rotors, are almost dust-free, and are extremely quiet

through all their lifespan. Besides, ceramic brake pads provide a stiff pedal feel at all

times thanks to the material’s incompressibility.

Their ability to handle and quickly dissipate high temperatures allows them to recover

quickly which is excellent for helping the rotors, the brake fluid, and the rest of the

braking system components cool and healthy. Also, heat reduction helps to reduce

braking distances and preventing fading.

It’s good to notice that dust-free is not only good for aesthetic purposes (keeping the

rims clean), it also helps to keep the caliper’s piston/s and the rotors’ surface clean,

which is another reason why ceramic brake pads are not only long-lasting but they

help to extend the service life of many parts of vehicles’ braking system.

If you enjoy extreme driving and you choose to upgrade your standard brake pads for

ceramics, you can buy a special set of brake disks to take the most profit from your

new pads.

They are made of different compounds, and while the formula varies depending on the manufacturer, they usually are made from a combination of iron, steel graphite, copper, a low proportion of organic materials, etc. The metallic part is mostly a combination of flaked metals which are used as friction elements.

Semi-metallic brake pads are tougher, more fade-resistant, and longer lasting than standard brake pads, but they don’t last as much as ceramic pads. Besides, because of the materials used for their construction, semi-metallic brake pads are much more aggressive to the rotors than ceramic and organic brake pads, reducing their service life and increasing the vehicles’ maintenance cost.

These compound come as OEM equipment in many mid-range, heavy-duty, and

vehicles where organic brake pads won’t be suitable, but not as fast or expensive

enough to come with ceramic brake pads as standard equipment.

Semi-metallic brake pads give a constant and firm pedal feel and can handle

extreme temperatures very well. The problem is that they get noisy over time, and

are not as easy on the brake rotors as ceramic or organic brake pads. They can cost

up to twice the price of organic brake pads and some brands and models are close

or matches the price of a good set of ceramic brake pads. Besides, they need more

force to be applied to the brake pedal to produce good braking torque.

They don’t produce as much dust as organic brake pads and in that department they

are close to ceramic brakes performance, they work well under a broad range of

temperatures and conditions, handle heat well, but they are noisier than ceramic

brake pads, and as they wear, they transfer vibrations to the braking system,

something that doesn’t happen with ceramic brake pads.

They don’t handle heat well, and the surface that is in contact with the rotor can crystalize, producing glazing, and reducing the brakes’ performance, which immediately translates into noisier brake pads and longer braking distances.

When used in small and light cars, they behave relatively well, but they are not advised for trucks or AWD vehicles, which are heavy and often exposed to extreme heat and hard driving conditions.

Even though they are cheap, organic brake pads need to be replaced sooner than any other, so if you add the labor cost of replacing them or the damage that crystallized brake pads can produce to brake rotors, they may end up not being as cheap as they appear.

Organic brake pads leave a remarkable quantity of debris as they wear out, which is also another point to keep in mind when comparing the difference between brake pad materials.